Flexible printed electronics

Flexible printed electronic technology is an emerging electronic technology that directly prints functional devices on flexible substrates such as plastics, textiles, paper or metal foil. Because flexible printed electronic technology has the characteristics and advantages of direct printing, short cycle from design to product, few process steps and flexible material selection, it has a wide range of application prospects in the fields of information, energy, medical care, and national defense, such as flexible electronic displays , Sensors, organic light-emitting diodes, printed RFID, thin-film solar panels, electronic newspapers, electronic skin/artificial muscles, etc. The key links of flexible printed electronic technology include design and simulation, substrates and materials, manufacturing processes and equipment, testing and quality control, etc. The core is micro-nano patterned manufacturing, involving multi-disciplinary cross-fields.

During the “Thirteenth Five-Year Plan” period, Harbin Institute of Technology Shenzhen campus will face the national key development of wearable electronic technology, and combine the development characteristics of strategic emerging industries such as Shenzhen’s information technology and new material technology, grasp the direction of international emerging academic development, and organize the school’s related discipline research The staff plans to build a "flexible printed electronic technology research center" to vigorously promote the leap-forward development of flexible printed electronic technology.

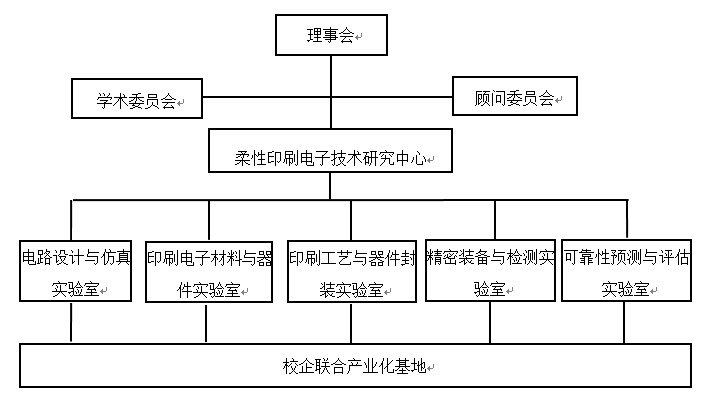

Institutional setting

The Flexible Printing Electronic Technology Research Center implements the director responsibility system under the leadership of the board of directors, and establishes an academic committee and an advisory committee. The director of the Flexible Printing Electronic Technology Research Center and the director of the academic committee are selected by the board of directors at home and abroad, and are held by outstanding scholars in the field of electronic manufacturing technology. The center has five research directions and a school-enterprise joint industrialization base.

At present, the disciplines involved in the center already have a scientific research and innovation and talent training team with reasonable structure, active academic thinking, good comprehensive quality, and strong ability, including full-time teachers and researchers, bi-base teachers and researchers, guest professors and research There are about 40 personnel in total, and there are about 150 PhD and master students. An international, high-level academic team has been formed, mainly full-time teachers from the Shenzhen campus, combined with the discipline advantages and characteristics of the headquarters of Harbin Institute of Technology.

Main research direction and industrialization base

The five research directions under the center include:

(1) Circuit design and simulation: involving the application and implementation of lightweight encryption algorithms in printed RFID, the research and implementation of printed RFID in different applications, and the application and implementation of lightweight storage devices in printed RFID; with intelligence Sensing printed RFID, the realization of various traditional electronic devices in printed 3D circuits, the advantages and disadvantages of traditional silicon electronics and printed electronics in the realization of 3D integrated circuits, 3D integrated circuits combining silicon electronics and printed electronics, and printed 3D circuits Research on the reliability testing methods and improvement of reliability.

(2) Printed electronic materials and devices: including quantum materials and devices, organic functional materials and devices, bio-intelligent materials and sensors, transparent conductive film materials and devices, and research on the physical and chemical processes of material surfaces and interfaces.

(3) Printing process and device packaging: In terms of using the printing process to produce high-precision graphics, the technical means of curing on the substrate is optimized to produce flexible conductive graphics that meet the requirements to meet the electrical interconnection function; printing in the functional structure of the device On the one hand, develop specific technical means to achieve the structure required by the design, and complete the functional structure of the device after curing. Develop packaging technology to enable the functional structure to perform stably in a specific working environment and ensure its service life.

(4) Precision equipment and testing: vigorously research and develop precision equipment suitable for printed electronics, research and develop new technologies to improve the accuracy of printed circuits; for high-viscosity conductive inks, improve inkjet printing technology and improve the reliability of printed circuits; develop inkjet Ink technology realizes ink droplets that are dimensionally stable and can be accurately controlled. Develop supporting detection technology and precision equipment for online real-time detection to realize electronic products with excellent performance.

(5) Reliability prediction and evaluation: Improving and improving the reliability of flexible printed electronics is the main goal of flexible device design and a prerequisite for its wide application. Research in this direction includes printed electronics fatigue failure research and design improvement; flexible substrates and Research on the mechanics and reliability of the heterogeneous interface of printed circuits; research on the ductility of printed circuits of nano-silver, nano-copper and other conductive metals or composite materials; research on new printed electronic packaging materials and reliability; research on finite element analysis of flexible printed electronics, etc.

The center also sets up a school-enterprise joint industrialization base, which is responsible for the promotion and transformation of a large number of valuable technological achievements formed by the center in the process of scientific and technological research. The base has three main functions: one is for the achievements that are suitable for promotion to social enterprises, the base is responsible for the completion of technology promotion and cooperation transformation; the other is for the achievements that need to be independently completed in the base for industrialization implementation, the base is directly responsible for the society Provide complete sets of equipment and products; the third is to serve as an application demonstration base for the introduction of foreign high-tech and equipment, reduce the cost and risk of introducing advanced electronic manufacturing technologies, and accelerate the application of the latest foreign manufacturing technologies.

The goal of building

The flexible printed electronic technology research center aims at the national goal, takes the major scientific basic issues of advanced electronic manufacturing technology as the lead, fully integrates the existing scientific research bases and discipline team resources, and produces landmark scientific research results through major scientific research projects and cultivates world-class Of scientists, to create a flexible printed electronic technology research and teaching base with internationally advanced level of interdisciplinary integration, superior resource sharing, excellent talent gathering, active international academic exchanges, and scientific and technological innovation to provide the core driving force for the sustainable development of my country’s electronic manufacturing industry .